Strong, durable, water-tight, aesthetic and stable in terms of design

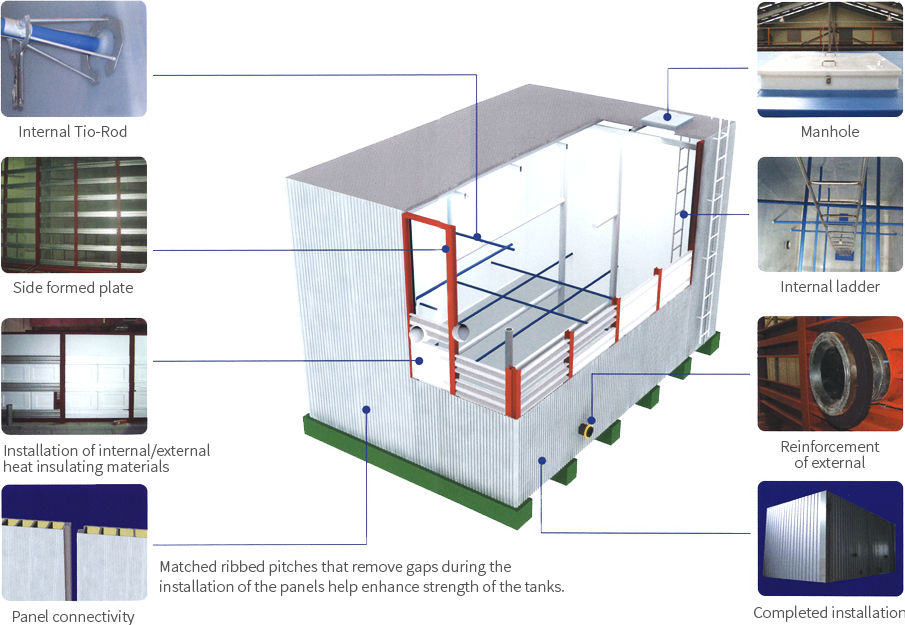

Process of Installing PDF water tanks

-

01

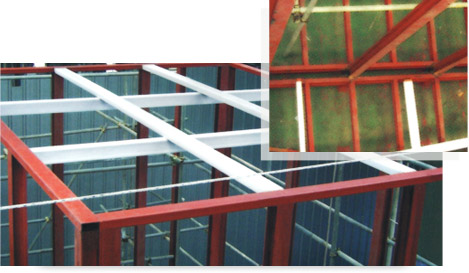

Installation of Base Frames and Framework

-

02

Partitions and Top Reinforcements

-

03

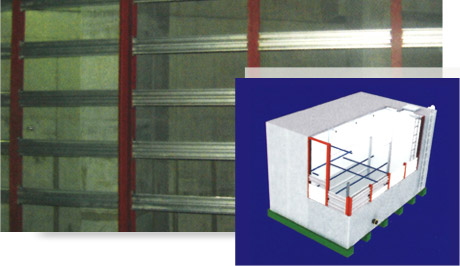

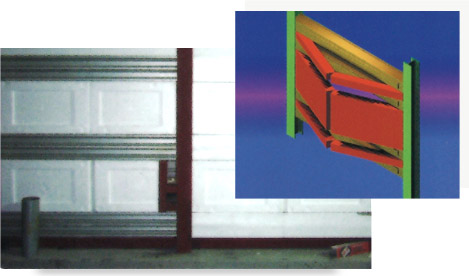

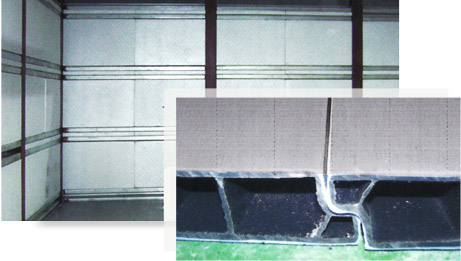

Reinforcement of the Side Forming Panels

-

04

Heat Insulating Materials

-

05

Installation of the Base Plate

-

06

Partitions and the Top Reinforcements

-

07

Sheet Pasting

-

Sheet pasting

-

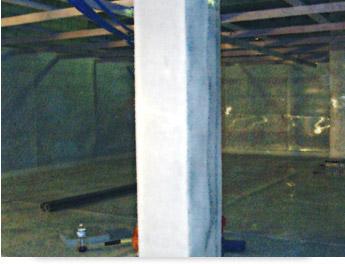

Column lining

-

Securing height for maintenance work

-

Pasting side sheets

-

Major Features of PDF Panel Tanks